TJR Consulting LLC – sales@tjrconsulting.net – p: 630-546-7031 - f: 509-472-8813 – P.O. Box 338, Saint John, IN, 46373

TJR Consulting LLC

Request a Quote for Weld Booth Automation

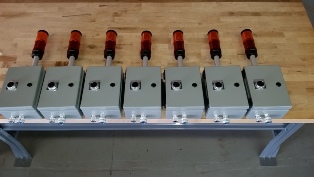

Example Below includes a Seven Booth System with Booth Active Light, Help Light, Help Pushbutton, and RFID reader on side of panel. Light panels are mounted at each booth and main panel in a central location within weldshop.

Sequence of Operation:

- Student logs into booth via RFID card assigned to him/her. Data is logged.

- Student presses help, if needed. Data is logged.

- Instructor Helps student and swipes his RFID. Data is logged showing which instructor helped and how long it took to get help.

- Student welds, grinds, etc. Data is logged and totaled in database

- Student finishes and Logs out via RFID. All times, dates, and activity is compiled on booth session.

- Panel design, fabrication, and installation drawings.

- All electrical components, RFID’s, lights, weld/grinding indication sensors.

- Server, software, reporting features, help push button

- Software includes booth monitoring, add/delete student access, searching for students, printing reports on students.

- All equipment needed for complete system.

- Electrical Installation Scope of Work Included. Electrical installation on-site not included.

- On-site setup and training.

Whats Included:

Please Fill out the Form Below to Receive a Weld Booth Automation Quote within 2 business days.